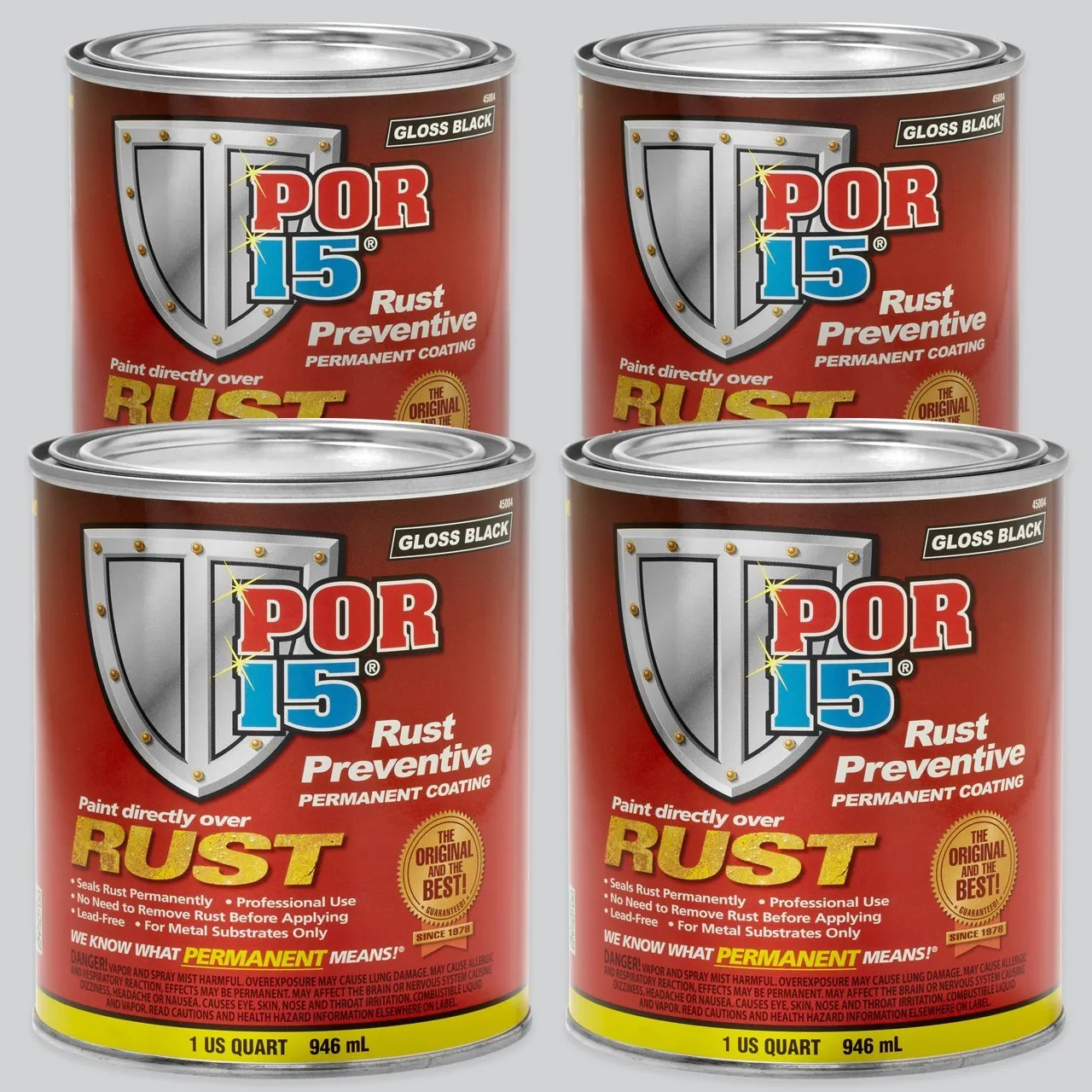

Purchase this POR-15 Quart Special of and save over the individual prices.

The ultimate rust preventive system for permanent corrosion protection. Purchase this POR-15 Quart Special of and save over the individual prices.

For best results always clean and prep metal before using the Rust Preventive Under Coating. The components of the . A topcoat is required if exposed to UV light. Black and Gray Rust Preventive Coatings are non-conductive and good for EV conversion applications.

Step 1: (Formerly Marine Clean) removes grease, oil, dirt, and grime in one application without leaving residues, noxious fumes, or flammable solvents.

Step 2: (Formerly Prep & Ready) provides the best adhesion for POR-15 Rust Preventive Coating on any metal surface, including shiny polished metal surfaces.

Step 3: is a high-tech, high-performance rust preventive coating designed for application directly on stable rust or seasoned metal surfaces. Provides permanent rust protection with a hammer-tough finish resistant to acids, alkalis, oils, fertilizers, and repels all fuels.

Step-by-step Restoration

Before: Heavily rusted diamond-plate pickup truck beds can be a problem, fix them permanently with the POR-15 3-Step System.

Step 1: Clean it! Remove loose rust and degrease the surface with a water-based Cleaner Degreaser

Step 2: Prep it! Neutralize rust and etch with Metal Prep.

Step 3: Coat it! After thorough washing and drying, coat with POR-15 Rust Preventive Coating, right onto the rust!

For areas exposed to U.V. light: Topcoat with Top Coat, 2K Urethane, or other paint of your choice.

After: Now you have a PERMANENTLY repaired truck bed, that won't rust again.

POR-15 Rust Preventive Coverage

POR-15 Rust Preventive Testing Results

Structural Strength Measures

ASTM C-580 Flexural Strength - measures flexural strength and modulus of elasticity. 5,200 pounds per square inch

ASTM C-579 Compressive Strength - measures compressive strength, the capacity of axially directed pushing forces. 12,500 pounds per square inch - Verified. Not tested to failure.

ASTM C-307 Tensile Strength - measures the tensile strength of cured chemical-resistant materials. 3,200 pounds per square inch

ASTM D-4541 Bond Strength To Concrete - measures the strength of coatings bond to concrete. Concrete fails before POR-15 Rust Preventive Coating. It far exceeds the tensile strength of concrete

Abrasion Resistance

ASTM C-501 Taber Abraser - abrasive wear by determination of the loss of weight resulting from abrasion. In two separate tests, POR-15 Rust Preventive had:

- No loss after 1,000 cycles with a 1,000 gram abraser

- Loss after 10,000 cycles with 1,000 gram abraser = 0.09 grams

Weather Resistance

Weatherometer - accurate weather resistance indicator of cycling of conditions. The cycle is 30 mins sun at 135 degrees F, 30% relative humidity and 30 mins dark at 75-80 degrees F, 100% relative humidity 1,000 hours of exposure equals 5 years of simulated exposure in the Rocky Mountain region. There was no change in the 3 panels coated with POR-15 Rust Preventive Coating exposed for 2,000 hours.

ASTM B-117 Salt Spray - specimens are exposed at specific locations and angles. It creates a 100% relative humidity condition in the exposure zone.Two separate B-117 tests. One with new bare steel and the other with rusted steel. Both were coated with POR-15 Rust Preventive Coating.

- No change in 3 panels of new steel exposed for 250 hours at 98 degrees. Thickness = 2 mils

- No change in 3 panels of rusted steel exposed for 1000 hours at 98 degrees. Thickness = 2 mils

Chemical Resistance

Chemical Bath Test - After 200 hours of soaking in the following chemical bathes, panels coated with POR-15 Rust Preventive Coating experienced no changes: 10% hydrochloric acid, 50% sulphuric acid, 55% chromate, 85% phosphoric acid, 10% sodium hydroxide 98% methanol.

Raw Sewage Test - A metal box that houses a filter for raw sewage in a treatment facility was coated with POR-15 Rust Preventive. After a year of service, no viable undercutting or rusting was present on the housing.

Impact, Porosity, and Temperature Tests

Mil-D-3134J Impact Resistance - POR-15 Rust Preventive Coating exceeds standards.

ASTM C-413 Water Absorption - method covers the determination of the absorption of chemical-resistant mortars, grouts, monolithic surfacings, and polymer concretes. 0.0001 maximum

NACE Stand TM0174 - 0.00 POR-15 Rust Preventive Coating is a non-porous coating.

Temperature Resistance - POR-15 Rust Preventive Coating is temperature resistant up to 450° continuously. A test showed that no adhesion was lost at 450° F for 10 hours.

![Nauticus Smart Tabs SX 9.5 x 10 - f/12-16 Boat w/40 - 80HP - White [SXW9510-40] Nauticus Smart Tabs SX 9.5 x 10 - f/12-16 Boat w/40 - 80HP - White [SXW9510-40]](https://www.streamflare.shop/image/nauticus-smart-tabs-sx-95-x-10-f12-16-boat-w40-80hp-white-sxw9510-40_4COtz9_285x.webp)